Here at Autoline Industries we offer a wide array of services, including CNC Turning and CNC Milling. While most of our clients are already intimately aware of actions behind each service, those less familiar may have difficulty identifying the variances between these seemingly similar processes.

Although on the surface they appear to complete similar actions and produce similar results, the operations of both CNC Turning and CNC Milling can vary greatly.

The Basics

CNC machining is a popular term in the manufacturing space, but what exactly does it mean? To put it simply, CNC, or ‘computer numerical control,’ machining is a subtractive manufacturing processes that uses pre-programmed computer software to dictate the tools and machinery. These cutting tools then shape stock materials, including metals, plastics, wood, composites, glass and more, into custom parts.

The entire machining process begins with the creation of a 2D or 3D CAD part design. After the design process, the machinist will export it into a CNC compatible file format and then convert it into a CNC machine program. The programmed machine dictates the actions of the tools to create a workpiece. Before the machine begins operating, the operator secures the workpiece to the worktable and attaches the machine tools to the spindle. The operator will program specifications into the machining application and cutting tools. The final step is to launch the program.

Moreover, two of the key CNC machining services we are focusing on include CNC turning and CNC milling. These are high-powered methods of producing refined products that may appear to be similar in operations but are surprisingly different in several aspects. This knowledge is important to know when choosing what service might deliver the best outcome for your vision. Continue reading to learn more!

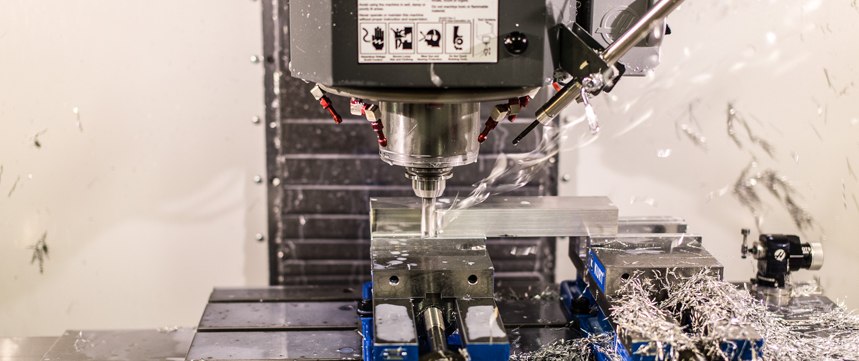

CNC Milling

Google defines milling as “to cut or shape metal using a rotating tool.” This is quite literally what it is. The machining process uses computerized controls and rotating multi-point cutting tools to shape and cut through material and create a custom designed piece. Commonly used material includes metals, plastic, and wood. The cutting tool rotates at speeds reaching up to thousands of RPM (Revolutions per minute) when the milling process begins.

Milling is the best service as a secondary finishing process. It supplies shape, definition, and produces features to a part such as holes, threads, pockets, and slots. The process includes removing material from an already cut piece of material to achieve the custom design preset into the computer. Furthermore, CNC milling machines are categorized into horizontal and vertical machine configurations. This means that if a machine rod is vertically oriented, then it is a vertical milling machine. And if the rod is horizontally oriented, it is a horizontal milling machine.

Furthermore, milling has many advantages over other manufacturing processes. CNC milling is a fast and effective way to produce components with a high degree of accuracy. It supplies a smooth finish and can produce any 2D or 3D shape so long as the machine can reach the needed cutting surface. Examples of CNC Milled parts include Automotive components, Molds, Firearms, Gears, Enclosures, Bracketry, Building, and Fabrication Components.

CNC Turning

CNC is a sub-category of lathing. What is lathing? It is a process much like milling but slightly different. In contrast to a milling machine in which the workpiece moves as it is cut, a lathe machine will hold the workpiece in place as it is cut. Not only does the lathe hold the piece in place, but it also rotates it. This is unlike milling where the workpiece is continually moving. Turning requires complete stabilization. One way to think of this is a pottery wheel. The clay is the workpiece, and the hands are the cutting tool. The spinning wheel is the lathe stationing the workpiece so that the potter can sculpt the clay.

Due to technological advancements, CNC lathe machines are quickly replacing other traditional production machines. Furthermore, turning encompasses several benefits including an easy set up and operation. It offers superior dimensional accuracy and high-quality finishes on all surfaces. In addition, turning supplies immense accuracy in production and repeatability.

Moreover, CNC turning is “a machining process that uses a cutting tool to remove material for creating cylindrical parts…” Like milling, it is another subtractive machining process. With turning, a spinning piece holds a workpiece in place as a cutting tool deducts material. However, unlike milling, turning focuses on creating a helical toolpath. Turning can also cut material like metal, wood, or plastic. In short, the biggest difference between milling and turning is that the latter requires a secure hold of the workpiece while the spinning tool does the cutting. In other words, the tool moves along a workpiece or a tool head shoots it.

Sometimes in turning, the spin tool will rotate the workpiece at high speeds and then cut the tool. The tools and workpiece in a milling machine will move simultaneously. It achieves this by moving a static cutting tool against the piece. Moreover, people choose milling for more complicated geometries. In contrast, others resort to turning for rotational, axisymmetric, cylindrical shapes with many features like grooves, tapers, and contoured surfaces.

Conclusion

While both forms of machining share many similarities and are even complimentary to each other, they each serve a key purpose and understanding these differences ultimately leads to better results. To learn more about CNC turning and milling, or one of the many other services we offer here at Autoline, contact us today! Our friendly and knowledgeable team is here to assist you. With our top of the line equipment, tools, and experience across a wide range of industries, we can help complete your next project.

Autoline’s Turning and Milling Services

Our top of the line CNC turning, and Milling services are the preferred method for removing large amounts of material on rounded stock as quickly and precisely as possible. Autoline houses state of the art machines ideal for larger production runs.

If you are looking for high volume, and quick turn around on simple components our CNC machining options are going to be provide you with the best service.