Every machine shop must adhere to a group of safety regulations and guidelines; primarily for the safety of the machinist, and second, for the sake of the business. Here at Autoline, we are aware of the dangers that can take place at any given time when on the floor, so we enforce additional protocols for caution. It is our mission to provide the best quality products on the market in a timely manner. The best way we can uphold that mission every day is to ensure we follow the set of rules created to foster a safe environment. We are always looking for ways to prevent an accident, so forming new rules is a way we stay proactive on this front.

Though some rules seem like common sense, they’re enforced because someone at some point in time over the course of machining history decided to test the risk and learned it wasn’t worth it. Since we’ve been in business, we’ve encountered very few and minimal accidents. This is because of our strong culture of safety. Outlined below are several of our basic but very fundamental rules we enforce here at Autoline.

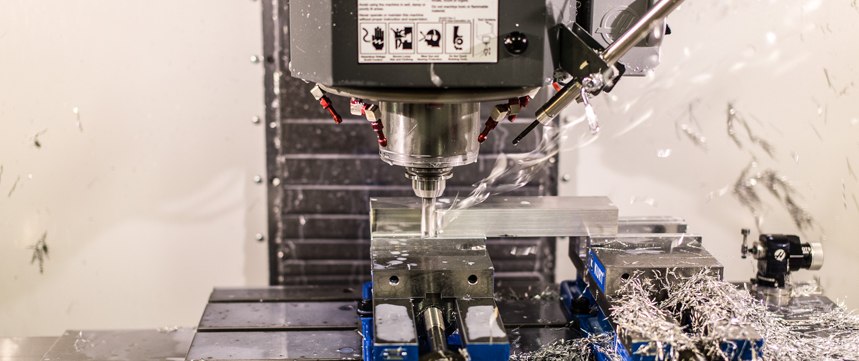

1. Keep machine doors closed

This is the most obvious safety rule on the shop floor. CNC Machine doors are large to accommodate the complex technology structure and functions inside. Although it might seem like common sense to keep the door shut when the machine is operating, not everyone knows. You may be surprised by the number of machinists who try to shave off a few seconds of operation time by disregarding this. There are so many safety risks at play when you open the door. A part of the tool can fly out of the machine, pieces of the stock, and even the stock itself can come soaring out the open doors and hit you. The extent of the injury varies, but it’s not worth finding out just how much.

Our machinists know this and ensure they complete the entire operation before opening the doors. Even if the cycle is nearing the end, rushing to open the doors can lead to coolant landing on you or worse, your machine malfunctioning. Trying to take short cuts can end unfavorably for the operator. So, we make sure every new machinist understands that this simple concept is extremely important for their safety.

2. Don’t alter the tools

Time and money are two variables constantly at stake for any industry. In machining, some operators will alter their machines to save time and money. This is a dangerous practice. Firstly, these highly powered, complex machines are designed to function in a specific way. When shops alter the tools to make them perform a job different from what it was designed to do, a substantial amount of damage can be done. Rather than risking it, we would upgrade to a modern machine that can provide the exact function we are looking for. Though it can be costly, it is safer to do this than damage the existing machine by forcing it to perform outside of its programmed abilities.

Another reason it is dangerous to alter the tools in a machine is that it can be expensive to repair. If something goes wrong because we decided to alter the tools in the machine, we could permanently damage it. Depending on the severity of the problem, it could cost close to the same amount of a new one. In addition, we personally believe that if we don’t have the machinery to perform or produce a specific function, it would be far more beneficial to us to purchase another machine. How? In addition to producing your project, we will also be broadening our own resources as a manufacturing facility. Ultimately, we know the benefits far outweigh the cost here.

3. Keep the machines maintained

Anyone who owns a machine knows that its lifespan is affected by how well it is maintained throughout time. Take for instance your car. If you’re not getting the oil changed, checking the fluids, replacing your engine filter, inspecting the tires, testing your brakes, and regularly washing it, you will increase the likelihood of damaging the vehicle. Preventative car care will reduce the wear and tear of your car’s components, extending its lifespan. If you don’t maintain the details, costs will add up and eventually more damage will occur totaling an even greater expense. The same rules apply to CNC machines. An unmaintained machine can cause damage to them, and repairs aren’t cheap. In addition, it can also pose several safety problems. Small issues can eventually lead to bigger problems if you don’t resolve it in a timely manner.

If you don’t maintain your machine properly, it can hinder the process of producing quality parts. For example, a dirty machine can cause malfunction in the interior system and derail precision while performing, resulting in a subpar product. To prevent all these issues from occurring, we train our machinists to clean the machines several times a day. After every cycle, machinists spray down the interior and then remove the excess metal. Moreover, we schedule our machines for regular maintenance, and even sometimes undergo unscheduled servicing for extra caution. Here at Autoline, we know the importance of maintaining our workspace and work tools as well. Everything our operators lay hands on are essential to completing the job. We treat everything in the workshop with care and attention to ensure we are always finishing each project with quality tools and in a reasonable time.

4. Keep staff trained

Last but certainly not the least! A major issue in our industry today is that unskilled workers are operating the shops. Not to say these individuals cannot acquire the necessary training, because they absolutely can. However, placing amateurs in an environment where they are unknowledgeable of all the dangers and unequipped to handle the outcome of consequential situations, is only setting them up for failure. Similarly, there are not as many skilled machinists in the field because automation has reduced the requirements of the job.

Technology has dealt the world a great deal in innumerable ways, but the expectation for machinists have narrowed the skill factor for many looking to establish themselves in the industry. To dispute this, we require our machinists to have a substantial background in machinery operation and are more likely to hire individuals with complimentary hobbies. We don’t take lightly the dangers of the job and therefore enforce strict rules and regulations. Moreover, our training is fairly extensive, and we require weekly meetings to communicate updates and to make sure machinists are adhering to protocols.